In the realm of food processing and manufacturing, extrusion technology plays a vital role in transforming raw ingredients into a wide variety of food products. Among the key components of a food extruder machine are the extruders themselves, which are responsible for the processing and shaping of the food mixture. Two primary types of extruders commonly used in the food industry are single screw extruders and double screw extruders. Each type has its unique characteristics, advantages, and applications. In this article, we will explore the differences between single screw and double screw extruders in food extrusion machines.

Single Screw Extruder:

A single screw extruder, as the name suggests, utilizes a single rotating screw within the extrusion barrel to push, mix, and shape the food material. The extruder barrel typically has a circular or hexagonal cross-section, which facilitates the compression and movement of the food mixture. Single screw extruders are commonly used in various food processing applications, including cereal manufacturing, snack production, pasta manufacturing, and pet food production.

Key Features and Advantages of Single Screw Extruders:

1. Simple Design: Single screw extruders have a relatively straightforward design with fewer components, making them easier to operate and maintain.

2. Cost-Effective: Single screw extruders are generally more affordable compared to double screw extruders, making them a cost-effective option for smaller food processing operations.

3. Versatility: Single screw extruders can process a wide range of food ingredients, from dry powders to moist pastes, and can produce various shapes and textures of food products.

4. Controlled Processing: The rotational speed of the single screw can be adjusted to control the processing time and temperature, allowing for precise control over the cooking and texturizing of the food mixture.

5. Suitable for Low-Viscosity Materials: Single screw extruders are well-suited for processing low-viscosity food materials, such as certain cereal-based products.

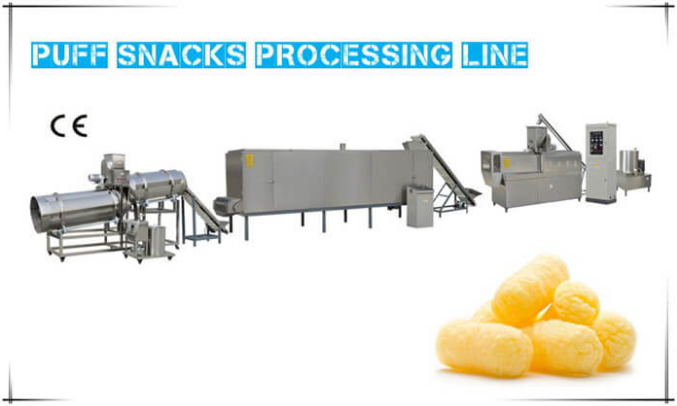

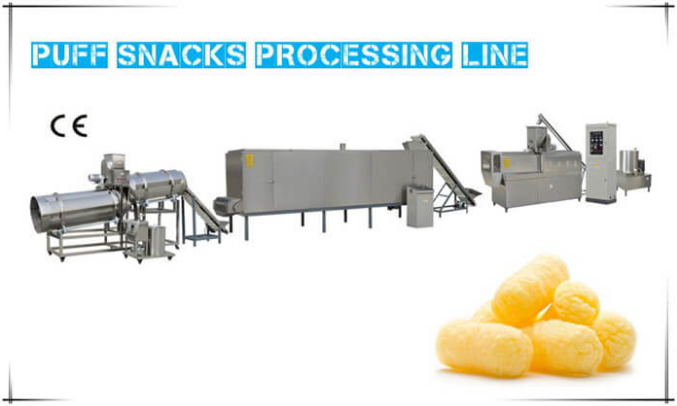

Puff Snacks Extruding Machine

Double Screw Extruder:

Double screw extruders, also known as twin-screw extruders, are equipped with two intermeshing screws within the extrusion barrel. These screws work in tandem to convey, mix, and process the food mixture as it moves through the extruder. Double screw extruders are widely used in the food industry for producing a diverse range of products, including snacks, breakfast cereals, baby food, and pet treats.

Key Features and Advantages of Double Screw Extruders:

1. Enhanced Mixing Capability: The presence of two screws in a double screw extruder provides superior mixing and kneading of the food mixture, ensuring even distribution of ingredients and consistent product quality.

2. Higher Throughput: Double screw extruders generally have a higher processing capacity and throughput compared to single screw extruders, making them suitable for large-scale food production.

3. Improved Process Flexibility: The co-rotating or counter-rotating screws in double screw extruders offer greater process flexibility, enabling the incorporation of a wide range of ingredients and allowing for precise control over the extrusion process.

4. Better Heat Transfer: The dual-screw configuration in double screw extruders promotes better heat transfer and mixing, resulting in efficient cooking and a more uniform product texture.

5. Handling of High-Viscosity Materials: Double screw extruders excel at processing high-viscosity food materials, such as meat and protein-based formulations, due to their excellent conveying and mixing capabilities.

Comparison and Selection Considerations:

When choosing between a single screw extruder and a double screw extruder for a food extrusion machine, several factors should be considered:

1. Processing Requirements: Evaluate the specific food products you intend to produce and their processing characteristics. If your applications involve a wide variety of ingredients and textures, a double screw extruder may be more suitable for its enhanced mixing capabilities.

2. Production Capacity: Consider the desired production capacity and throughput. Double screw extruders are generally preferred for high-volume production, while single screw extruders are more suitable for smaller-scale operations.

3. Ingredient Types: Analyze the types of ingredients you will be using in your food formulations. If you plan to work with high-viscosity materials or complex mixtures, a double screw extruder may be the better choice.

4. Budget Constraints: Budgetary considerations play a significant role in the selection process. Single screw extruders are typically more budget-friendly, making them a preferred option for smaller food processing facilities with limited financial resources.

5. Maintenance and Training: Evaluate the availability of skilled operators and maintenance personnel. Single screw extruders generally have simpler designs and may require less specialized training for operation and maintenance.

Conclusion:

Both single screw and double screw extruders are valuable tools in the food industry, each with its unique advantages and applications. The choice between the two depends on the specific processing requirements, production capacity, ingredient types, budget constraints, and available expertise. By understanding the differences and capabilities of single screw and double screw extruders, food manufacturers can make informed decisions to optimize their production processes and meet the demands of the market.

If you want to know more information about food extrusion machine, please contact us. We will provide professional answers