Twin-screw extruders offer several advantages for food extrusion processes. These advantages contribute to improved product quality, increased productivity, and greater flexibility in food manufacturing. Below are the key advantages of twin-screw extruders for food extrusion:

1. Enhanced Product Quality:

Twin-screw extruders provide precise control over processing parameters such as temperature, shear, and residence time. This control allows for optimized cooking, mixing, and shearing of food ingredients, resulting in improved product quality, texture, and taste.

2. Consistent and Uniform Processing:

The intermeshing screws of twin-screw extruders ensure thorough mixing, blending, and dispersion of ingredients. This leads to a uniform distribution of flavors, colors, and additives throughout the product, ensuring consistency in taste, appearance, and texture.

3. Wide Range of Product Options:

Twin-screw extruders offer versatility in producing a wide range of food products. By adjusting the screw configuration, barrel temperature, and processing conditions, manufacturers can create diverse products with different shapes, sizes, textures, and nutritional profiles. This flexibility allows for innovation and the ability to meet diverse consumer demands.

4. Rapid Processing Time:

Twin-screw extruders operate continuously, enabling fast and efficient processing. This leads to reduced production time and increased productivity compared to traditional batch processing methods. The continuous nature of extrusion allows for high-volume production and efficient use of resources.

5. Energy Efficiency:

Twin-screw extruders are designed to maximize energy efficiency. The intermeshing screws reduce energy requirements for material transport, mixing, and processing, resulting in lower energy consumption per unit of production. This leads to cost savings and reduced environmental impact.

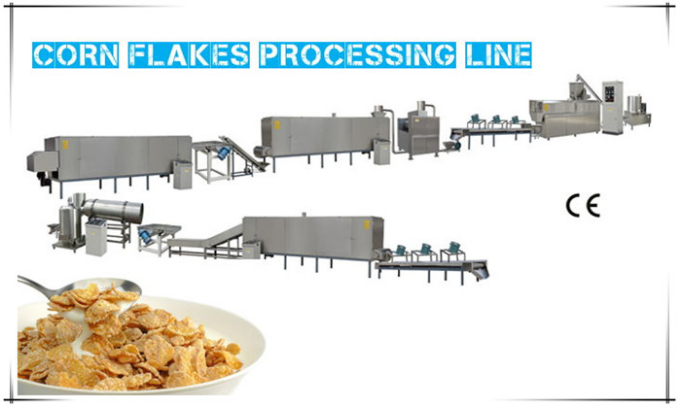

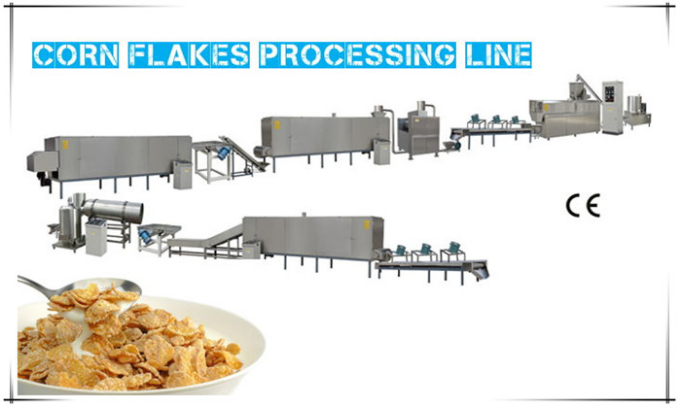

Corn Flakes Processing Line

6. Uniform Cooking and Pasteurization:

Twin-screw extruders offer precise control over cooking and pasteurization processes. The ability to maintain consistent temperature profiles and residence times ensures thorough cooking or pasteurization, resulting in food products that are safe, free from pathogens, and have extended shelf life.

7. Controlled Expansion:

Twin-screw extruders provide precise control over the expansion process, which is crucial for the production of expanded snacks, cereals, and other extruded products. By adjusting the screw speed, temperature, and moisture content, manufacturers can achieve the desired product density, size, and texture.

8. Reduced Ingredient Waste:

Twin-screw extruders facilitate efficient utilization of ingredients. The intermeshing screws ensure thorough mixing and dispersion of additives, reducing the risk of ingredient segregation or waste. This allows for better control over ingredient utilization and cost savings.

9. Easy Scale-Up and Process Optimization:

Twin-screw extruders allow for easy scale-up from lab-scale to commercial production. The modular design, adjustable screw configuration, and precise process control facilitate process optimization and seamless transition to larger production volumes. This flexibility helps manufacturers meet growing market demands efficiently.

10. Hygienic Design and Easy Cleaning:

Twin-screw extruders used in the food industry are designed with hygiene and sanitation in mind. They are constructed using food-grade materials, feature smooth surfaces, and are designed for easy cleaning and maintenance. This ensures food safety, minimizes cross-contamination risks, and reduces downtime during cleaning and changeovers.

11. Reduced Need for Additives:

The extrusion process in twin-screw extruders allows for the efficient processing and transformation of raw ingredients. This often eliminates the need for certain additives or reduces their quantities, leading to cleaner labels, healthier products, and enhanced consumer appeal.

12. Process Flexibility:

Twin-screw extruders offer process flexibility, allowing manufacturers to experiment with different formulations and optimize processing conditions. This enables rapid product development, innovation, and the ability to meet changing market trends and consumer preferences.

Conclusion

In summary, twin-screw extruders provide numerous advantages for food extrusion processes, including enhanced product quality, increased productivity, energy efficiency, process flexibility, and the ability to produce a wide range of food products. These advantages make twin-screw extruders a valuable tool in the food industry, enabling manufacturers to produce high-quality, innovative, and market-ready food products efficiently.

If you want to know more information about food extrusion equipment, please contact us. We will provide professional answers.