Cat Litter Production Line

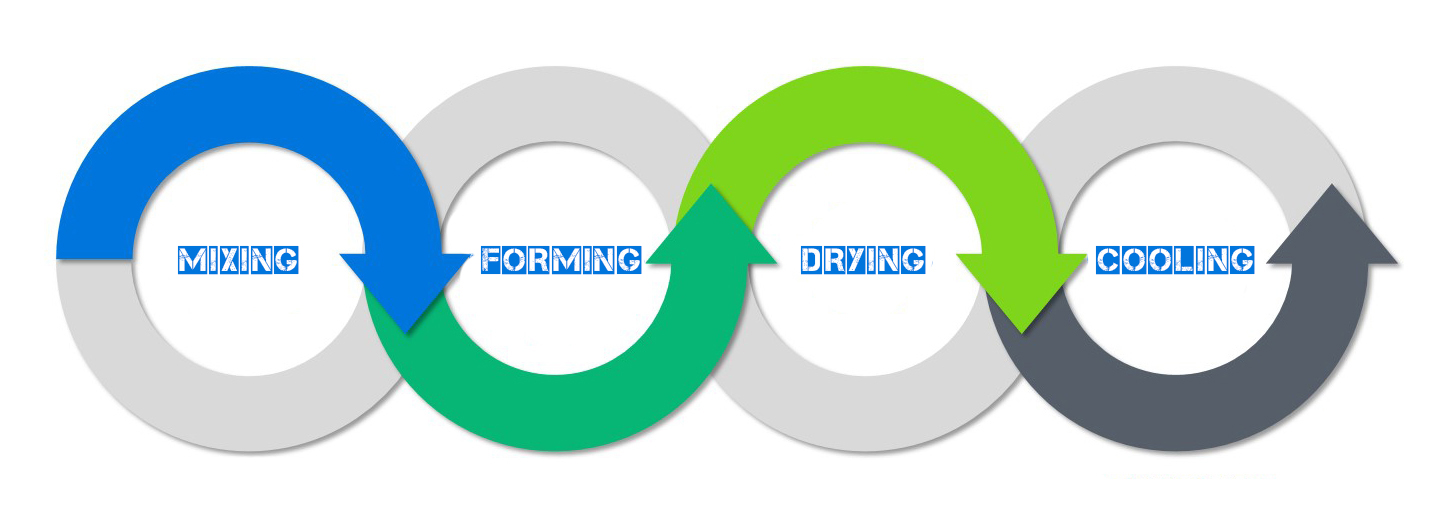

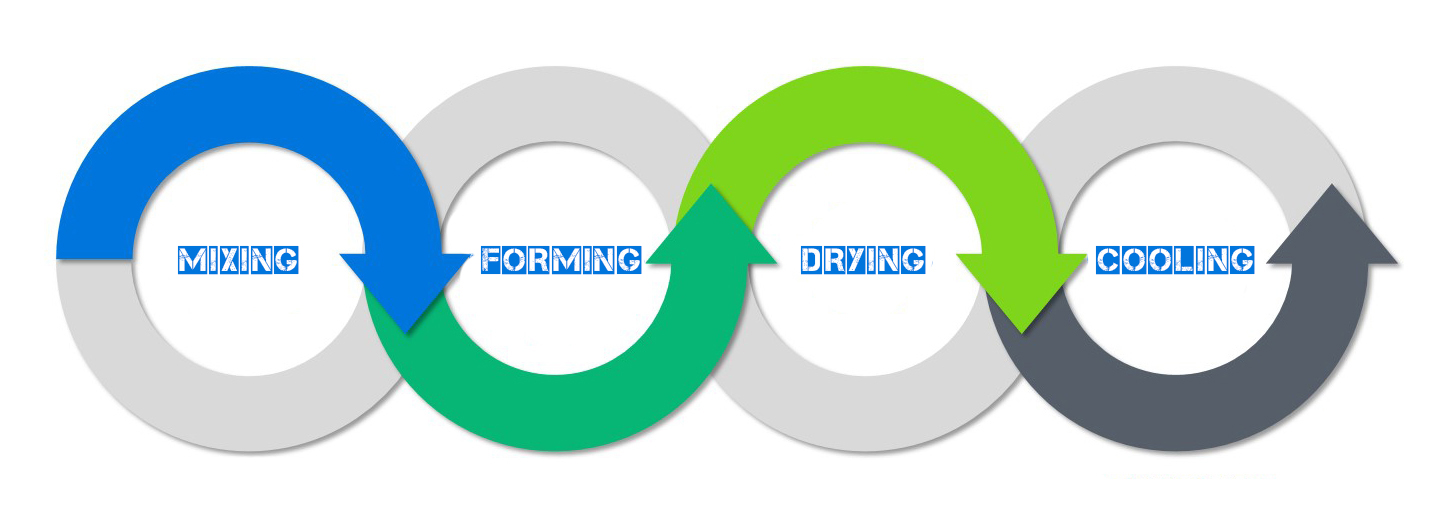

Production Steps of Cat Litter Production Line

The cat litter production process involves several key steps, ensuring the creation of a high-quality and efficient cat litter product. Here's an expanded description of each step in the cat litter production line:

Raw Material Crushing

The journey begins with the raw materials, which are typically minerals such as bentonite clay, silica gel, and activated carbon. These materials must first be reduced to a fine powder to create a suitable base for the cat litter. This crucial step is accomplished through the use of a hammer mill. The choice of raw materials will vary based on the specific type of cat litter being produced, such as clumping or non-clumping varieties.

Mixing of Raw Materials

Once the raw materials have been finely crushed, they are mixed together in a specialized mixer. The exact combination and proportions of the ingredients depend on the desired characteristics of the cat litter. For instance, bentonite clay is often used for clumping litters due to its moisture-absorbing properties, while silica gel may be added for improved odor control.

Pellet Formation

After thorough mixing, the blended raw materials are transformed into pellets. A pellet mill is employed for this purpose. The size and density of the pellets can be adjusted to meet the specific requirements of the cat litter product. This step is vital for creating the granules that are easy for cats to use and manage in their litter boxes.

Drying Process

To achieve the desired moisture content and ensure the cat litter's structural integrity, the freshly formed pellets are subjected to a drying process. The choice of dryer depends on the type of cat litter being produced. Common dryer types include rotary dryers, which use rotation to facilitate even drying, and flash dryers, which utilize high-temperature air to quickly eliminate moisture.

Screening and Quality Control

Following the drying process, the pellets undergo screening to remove any dust, debris, or irregularly sized particles. This quality control step ensures that the final cat litter product meets the desired standards in terms of particle size and cleanliness. Ensuring that the litter is free from impurities is essential to maintain the health and hygiene of cats and their owners.

Packaging and Distribution

Once the cat litter pellets have passed the quality control measures, they are ready for packaging. The cat litter is typically packaged in bags or containers suitable for retail sale. The packaging may include branding, information about the product's features, and usage instructions. After packaging, the cat litter is then shipped to retailers, making it available to cat owners and pet stores.

The cat litter production line is a carefully orchestrated process that combines science and engineering to create a product that meets the needs of cat owners while maintaining the well-being of their feline companions. The versatility of the production line allows for the production of various cat litter types, each tailored to specific cat owner preferences and cat hygiene needs.

Components of Cat Litter Production Line

Here is a more detailed overview of the different machines that are typically used in a cat litter production line:

Hammer mill: The hammer mill is used to crush the raw materials into a fine powder.

Mixer: The mixer is used to mix the raw materials together.

Pellet mill: The pellet mill is used to form the raw materials into pellets.

Dryer: The dryer is used to dry the pellets.

Screener: The screener is used to remove any dust or debris from the pellets.

Packaging machine: The packaging machine is used to package the pellets into bags or other containers.

Cat litter production lines can be either manual or automated. Manual production lines require more labor, but they are less expensive to set up and operate. Automated production lines are more expensive to set up and operate, but they can produce cat litter more efficiently and with less labor.

Cat litter production lines are used by a variety of businesses, including pet food companies, cat litter companies, and private label companies. If you want to know more information about cat litter production lines , please contact us. Qunlong will provide professional answers.