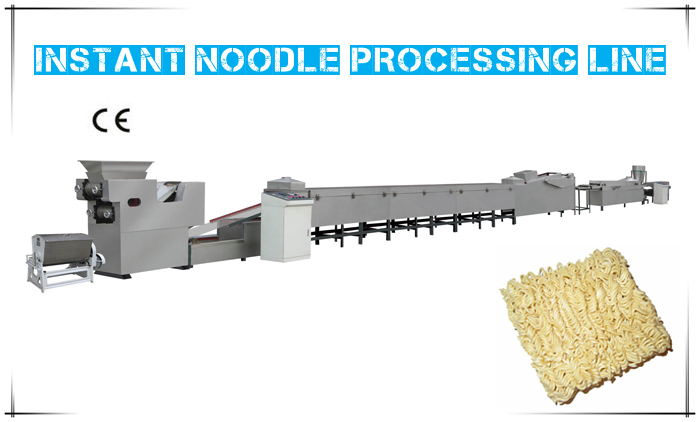

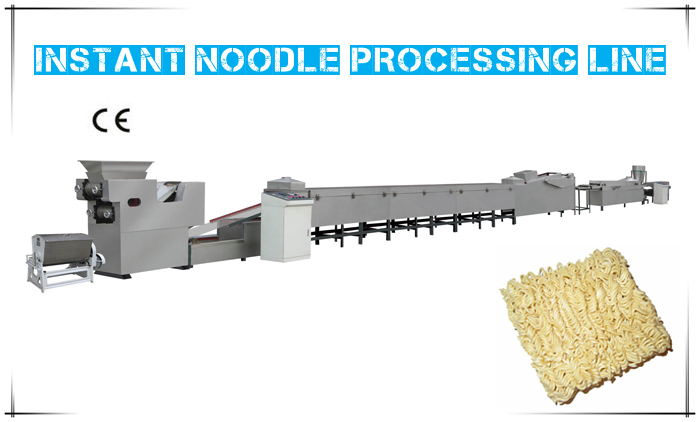

Instant Noodle Processing Line, as common extruder equipment, is used in the plastics processing industry, but currently, it is

mainly high-power in China. If it is not energy-saving, it will consume a lot of

resources. In fact, during the operation, Master some skills, you can do new to power saving.

In the process of starting heating, Food Extrusion Equipment turns on the temperature of several segments at the same time to start heating.

Of course, this method is also commonly used, but this often occurs after the temperature of the screw reaches a certain index. The temperature has not yet

reached (the steel of the die head is relatively thick and the area is

relatively large), so in this case, people generally heat the screw, and then

wait for the temperature of the die head to slowly rise to the set temperature

before starting to start. This approach is the most power-efficient.

Instant Noodle Processing Line

Of course, there is another thing to pay attention to. In fact, a simple sequential heating can help you save a lot of power in the process of warming up

and starting. When the temperature of the screw reaches When setting the

temperature, you start to remember the time, and then wait for the time when the

die temperature reaches the set temperature. There is a time gap here, that is,

between the screw reaching the set temperature and the die reaching the set temperature. How many minutes is the time gap? Find out this time difference,

the next time you turn on the machine, you can warm up the die so long before the number of this time difference, and then turn on the screw to warm up after reaching this time difference, which can also save power.

Extruder maintenance

1. The extruder is not allowed to run empty, so as not to damage the screw

and the machine.

2. If abnormal noise occurs when the extruder is running, it should be

stopped immediately for inspection or repair.

3. Machine parts to be inspected: It is necessary to pull out the screw for inspection, measurement and identification, and replace the parts that have

reached the prescribed wear limit according to the wear of the parts, and repair

the damaged parts.

4. Time for regular maintenance: We usually stop for regular maintenance after the twin-screw extruder runs continuously for 2500-5000h.

5. When the extruder needs to be stopped for a long time, the screw of the extruder should be placed in the machine do not take out, and the working surface such as the head is coated with anti-rust grease. Calibrate the

temperature control instrument regularly to check the correctness of the adjustment and the sensitivity of the control.

6. prevent metal or other debris from falling into the hopper, so as not to damage the screw and barrel. In order to prevent iron debris from entering the

barrel, a magnetic frame can be installed at the material inlet of the barrel;

or the material must be sieved in advance.

We are Kurkure Extruder Manufacturer, welcome to

consult.