As the demand for high-quality and nutritious dog food continues to grow, manufacturers are turning to advanced technology to meet the needs of pet owners. One such technology is the dog food machine production line, which offers consistent quality and efficiency in manufacturing. In this article, we will discuss the benefits of using a dog food machine production line and how it ensures the production of healthy and nutritious dog food.

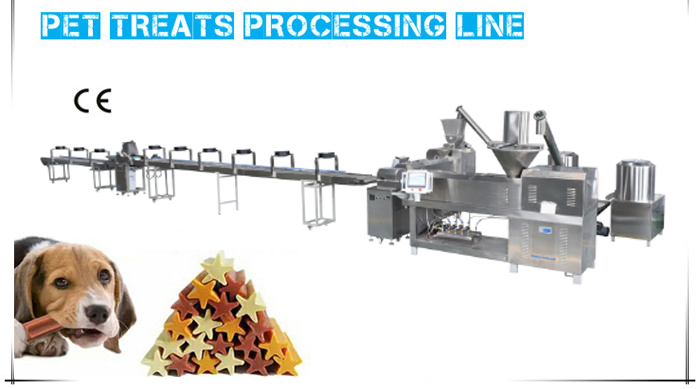

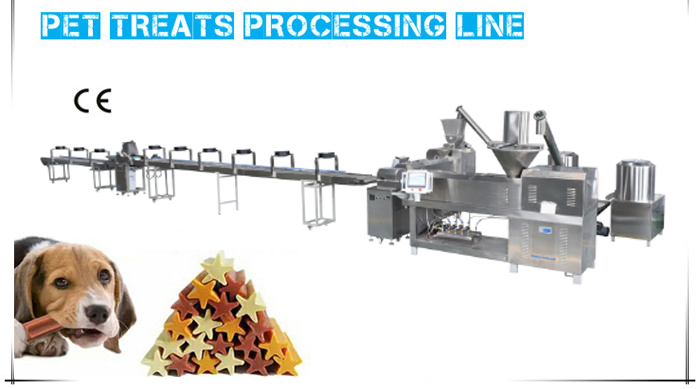

Pet treats extrusion line

What is a Dog Food Machine Production Line?

A dog food machine production line is a molded pet snacks equipment which is a series of interconnected machines that are designed to manufacture dog food on a large scale. The production line typically includes machines for grinding, mixing, extruding, drying, and packaging. The entire process is automated, which ensures consistent quality and efficiency in manufacturing.

Benefits

Consistent Quality: A dog food machine production line ensures consistent quality in manufacturing by automating the entire process. The machines are programmed to follow precise recipes and proportions, which ensures that every batch of dog food is the same. This consistency in quality helps to build trust with pet owners, who can rely on the product to meet their dog's nutritional needs.

Efficiency: A dog food machine production line is highly efficient, which means that it can produce a large volume of dog food in a short amount of time. The automated process eliminates the need for manual labor, which reduces the production time and increases productivity.

Cost-Effective: Using a dog food machine production line can be cost-effective for manufacturers. The automated process reduces labor costs and improves production efficiency, which can help to lower the overall cost of manufacturing.

Customizable Recipes: Manufacturers can customize their dog food recipes according to the nutritional needs of different dog breeds and sizes. The dog food machine production line can be programmed to follow specific recipes and proportions, which ensures that every batch of dog food meets the specific nutritional requirements of different dogs.

How a Dog Food Machine Production Line Ensures Quality and Nutrition

Grinding: The first step in the production line is grinding the ingredients. The machine grinds the ingredients to a fine consistency, which ensures that the dog food is easy to digest and absorb.

Mixing: The machine mixes the ground ingredients with water and other additives, such as vitamins and minerals. The mixing process ensures that the dog food is well-balanced and meets the specific nutritional needs of different dogs.

Extruding: The extruder shapes the mixture into specific sizes and shapes, such as kibble. This process ensures that the dog food is easy to eat and satisfies the dog's natural chewing behavior.

Drying: The dryer removes the moisture from the dog food, which helps to preserve its freshness and prevent spoilage.

Packaging: The final step is packaging the dog food in airtight containers, which helps to maintain its freshness and prevent contamination.

Conclusion

A dog food machine production line is a valuable tool for manufacturers who want to ensure consistent quality and efficiency in manufacturing. The automated process ensures that every batch of dog food meets the specific nutritional needs of different dogs and is well-balanced and nutritious. By using a dog food machine production line, manufacturers can produce large volumes of dog food in a cost-effective and efficient manner, which helps to meet the growing demand for high-quality and nutritious dog food.

Are you interested in learning more about dog food machine production line? Contact us today to secure an expert consultation!