Puffed food is a new type of food developed in the world in recent years.

It uses grain, beans, potatoes, vegetables and other raw materials, through puffing equipment processing, to produce a wide variety of, beautiful appearance, rich nutrition, crisp and delicious food.

Therefore, a large category of food has been uniquely formed.

Because of its simple structure, convenient operation, low equipment investment and quick effect, the equipment for producing this kind of puffed food develops rapidly and shows great vitality.

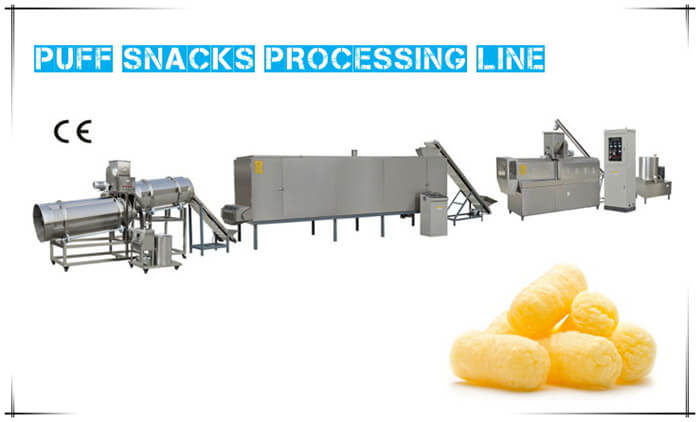

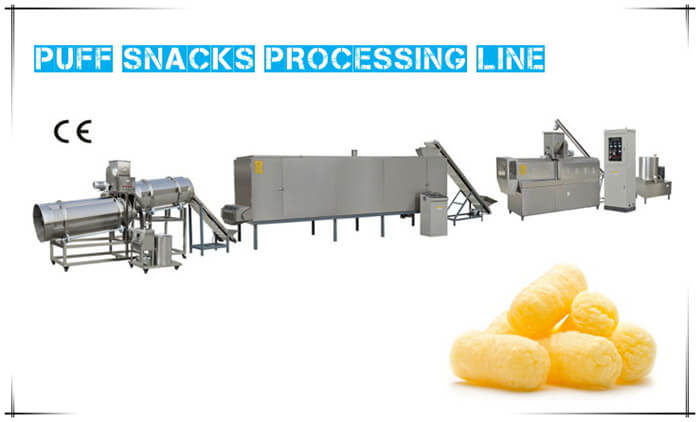

Puff Snacks Extruder

According to the types of products, puffed foods can be divided into three categories:

1. Puffed food made from corn and potatoes.

2. Plant protein is used as raw material to produce tissue protein food.

3. Using cereals, beans or potatoes as raw materials, the staple food is made after extrusion.

Although puffing technology belongs to physical processing technology, it also has its own characteristics.

Puffing can not only change the shape and state of raw materials, but also change the molecular structure and properties of raw materials to form some new substances.

The production principle of puffed food:

Put the grain into the extruder and add pressure with heating to overheat the moisture in the grain and soften the grain itself.

When a certain high pressure is reached, turn on the extruder.

When it is covered, the high pressure quickly changes to normal pressure.

At this time, the superheated water in the grain will vaporize instantly, resulting in a strong explosion.

Water molecules can expand about 2000 times.

The huge expansion pressure not only destroys the grain, but also destroys the molecular structure of the grain, shortening the insoluble long-amylopectin to water-soluble short amylose, dextrin and sugar, so the insoluble substances in puffed foods decrease and the water-soluble substances increase.

Advantages of using Extrusion Technology to produce expanded Food.

1. High preservation rate and digestibility of nutrients.

The protein-rich plant raw materials are extruded at high temperature for a short time, the protein is completely denatured, and the tissue structure is porous, which is conducive to contact with human digestive enzymes, improve the utilization rate and protein digestibility; the product is not easy to produce regeneration phenomenon.

In the process of keeping cereal food fresh, retrogradation is a common problem.

As a result of recycling, the taste of the product becomes rough and the digestibility is greatly reduced.

2. Give the product better nutritional value and functional characteristics.

When using extrusion technology to process cereal foods, additives such as amino acids, proteins, vitamins, minerals, food pigments and flavors can be evenly distributed in the extrusions and combine irreversibly with the extrusions.

They can achieve the purpose of fortified food.

Because extrusion and puffing are carried out instantly at high temperature, the loss of nutrients is very small.

3. It is easy to eat and has a wide variety.

Adding different excipients to raw materials such as grains, beans, potatoes or vegetables, and then extruding them, a wide variety of and nutritious expanded food can be produced; because extruded food has become cooked food, most of them are ready-to-eat food (ready-to-eat food), which is convenient to eat and saves time. It is a kind of convenient food with great development prospects.

Points for attention in purchasing puffed food:

1. Choose a brand.

Brand-name products produced by well-known enterprises sold in large shopping malls and supermarkets are preferred.

2. Look at the sign.

Buy prepackaged products and pay attention to product labels.

When buying, you should pay special attention to the production date of the product, and choose the product within the shelf life, preferably the product that has just been produced.

3. Most puffed foods are filled with inert gas in the bags to prevent oil oxidation and rancidity.

If the packing is found to be flat, consumers should not buy it.

4. We should try to buy expanded food in sealed packaging, because the quality of packaged expanded food is generally better, and puffed food sold in bulk is prone to rancidity due to exposure to the air, exceeding the hygiene target.

Puffed food production line of Jinan Qunlong Machinery Co., Ltd.

The puffed food production line integrates mixing, curing, puffing and molding, without the need for a boiler.

The production process is simplified, efficient, environmentally friendly and low-carbon.

The food produced by this production line is very popular because of its various colors, crisp and non-greasy taste.