The pet treats industry has experienced remarkable growth, driven by the demand for healthy, tasty, and nutritionally beneficial options. Behind the scenes, advanced technology, such as the pet treats extrusion line, is revolutionizing the production process, enabling manufacturers to meet the evolving needs of pets and pet owners.

Benefits of Pet Treats Extrusion Line

Efficient Production and Consistent Quality

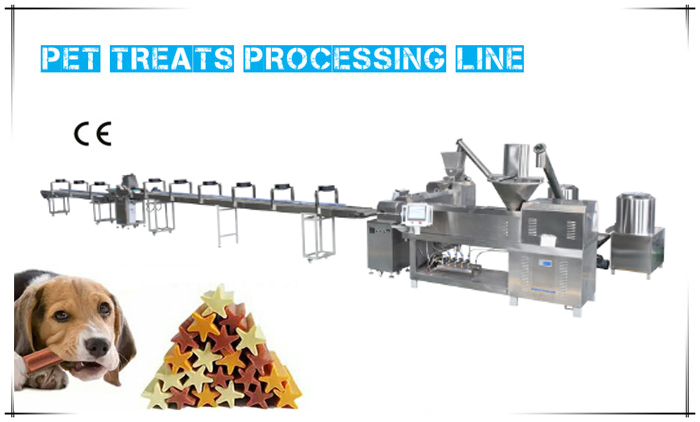

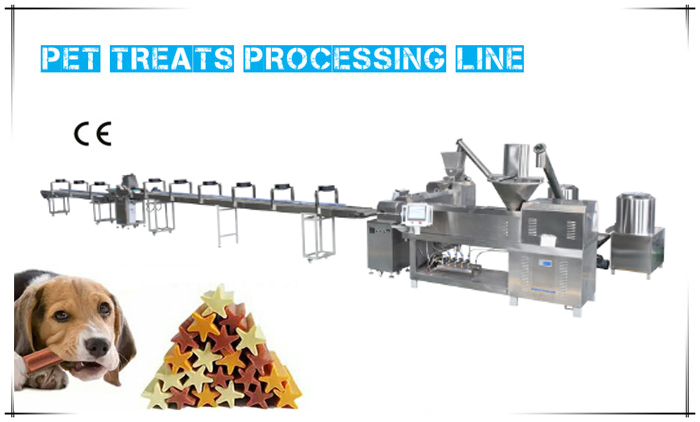

The pet treats extrusion line is a state-of-the-art system designed to streamline the manufacturing process while ensuring the highest quality standards. The extrusion process involves the use of specialized machinery that combines ingredients, forms them into desirable shapes, and cooks them to achieve optimal taste, texture, and nutritional content.

Versatility in Recipe Formulation

One of the key advantages of the pet treats extrusion line is its versatility in recipe formulation. Manufacturers can create a wide variety of treats tailored to specific pet preferences and dietary requirements. Whether it's crunchy biscuits, chewy jerky, or dental sticks, the extrusion line can handle a range of ingredients, including meat, grains, vegetables, and supplements. This flexibility allows for innovation and customization, keeping pets engaged and satisfied.

Consistency in Texture and Shape

Pet treats are not only meant to be delicious but also appealing in texture and shape. The extrusion line employs advanced shaping and cutting mechanisms, resulting in uniform treats with consistent texture and size. This consistency enhances the overall consumer experience by maintaining a familiar product appearance, making it easier for pets to chew and enjoy their treats.

Safety and Hygiene Standards

The pet treats extrusion line prioritizes safety and hygiene throughout the production process. The equipment is designed with materials that comply with strict food-grade standards, preventing any potential contamination. The automated nature of the line reduces human contact with the treats, minimizing the risk of contamination further. Additionally, the extrusion process includes high-temperature cooking, eliminating harmful bacteria and pathogens, ensuring that the treats are safe for consumption.

Increased Production Efficiency

With the growing demand for pet treats, manufacturers require efficient production systems to meet consumer needs effectively. The pet treats extrusion line offers increased production rates, reducing manufacturing time and costs. Automated processes, such as ingredient mixing, extrusion, shaping, and packaging, optimize productivity and minimize manual labor. Manufacturers can now produce larger quantities of treats in less time, ensuring a consistent supply to meet market demands.

Meeting Consumer Expectations

Pet owners have become more discerning in their choice of pet treats, seeking high-quality options that align with their values. The pet treats extrusion line enables manufacturers to produce treats that cater to these evolving consumer expectations. From all-natural and organic ingredients to sustainable packaging solutions, the extrusion line facilitates the creation of treats that resonate with eco-conscious pet owners.

Conclusion

The pet treats extrusion line represents a significant advancement in the pet food industry, benefiting both pets and their owners. It offers unparalleled versatility in recipe formulation, enhanced nutritional value, and consistent quality. If you want to know more information about pet treats extrusion line, please contact us. We will provide professional answers.