Puff snacks extruders are an essential piece of machinery in the snack food industry, used to produce a wide variety of puff snacks such as chips, crackers, and cereals. These snacks are made by heating and pressurizing a dough or batter mixture until it expands and puffs up, creating a light and airy texture. Puff snack extruders are highly efficient and can produce large quantities of snacks in a short amount of time. In this article, we will take a closer look at how puff snack extruders work and the various types available on the market.

Puff snack extruders consist of several key components, including a feeding system, an extrusion barrel, and a shaping die. The feeding system is used to introduce the dough or batter mixture into the extrusion barrel, which is typically heated to a high temperature to help the mixture expand and puff up. The extrusion barrel is equipped with a series of screws that rotate and mix the dough or batter as it is pushed through the barrel. The shaping die is a metal mold with a specific shape that determines the final shape of the snack.

There are two main types of puff snack extruders: single-screw and twin-screw. Single-screw extruders are the most common type and are used for producing a wide variety of puff snacks. They consist of a single screw that rotates and mixes the dough or batter as it is pushed through the extrusion barrel. Twin-screw extruders, on the other hand, have two screws that rotate in opposite directions and are typically used for producing more complex snack shapes or for incorporating multiple ingredients into the dough or batter mixture.

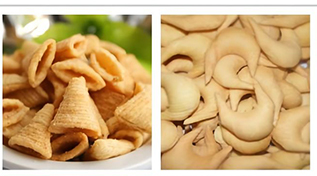

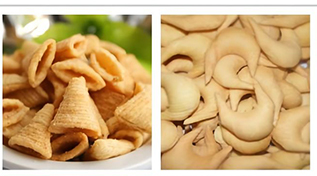

Puff snack extruders can be used to produce a wide variety of puff snacks, including chips, crackers, and cereals. Chips are made by extruding a dough or batter mixture through a shaping die with a thin, flat shape. Crackers are similar to chips but are typically made with a harder dough or batter mixture and have a more rigid texture. Cereals are made by extruding a dough or batter mixture through a shaping die with a small, round shape and are often flavored and sweetened.

One of the main advantages of using a puff snack extruder is the high level of efficiency and consistency it offers. These machines can produce large quantities of snacks in a short amount of time and can be programmed to produce snacks with very specific shapes and sizes. Additionally, puff snack extruders are highly versatile and can be used to produce a wide variety of snack flavors and textures by simply changing the ingredients in the dough or batter mixture.

In conclusion, puff snack extruders are an essential piece of machinery in the snack food industry, used to produce a wide variety of puff snacks such as chips, crackers, and cereals. These machines are highly efficient and offer a high level of consistency, and can be used to produce a wide variety of flavors and textures by simply changing the ingredients in the dough or batter mixture.

If you want to improve the efficiency of your puffed food production, come and contact us to buy it.