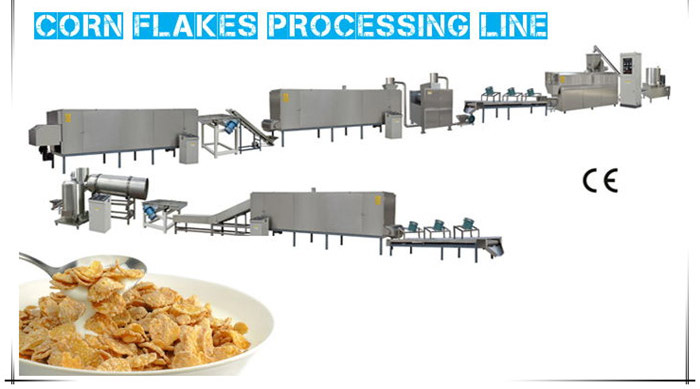

Corn flakes are a popular breakfast cereal that is enjoyed by millions of people worldwide. The process of making corn flakes involves several steps, including extrusion, cooking, and shaping. The corn flakes extrusion line is a set of machines used in the production of corn flakes.

This article will discuss the corn flakes extrusion line, its components, and the manufacturing process.

Components of a Corn Flakes Extrusion Line

The corn flakes extrusion line consists of several components, each with a specific function. These components include:

Mixer: The mixer is used to blend the raw materials, including cornmeal, sugar, and salt.

Extruder: The extruder is the heart of the corn flakes extrusion line. It is used to cook the mixture of cornmeal and other ingredients and shape it into the desired form. The extruder consists of a barrel, a screw, and a die.

Flaking Machine: The flaking machine is used to flatten the extruded mixture into thin flakes. It consists of two rollers that press the mixture into flakes.

Drying Oven: The drying oven is used to remove moisture from the flakes, making them crispy.

Sugar Coating Machine: The sugar coating machine is used to add a layer of sugar to the corn flakes, giving them a sweet taste.

Packaging Machine: The packaging machine is used to pack the corn flakes into bags, boxes, or other containers.

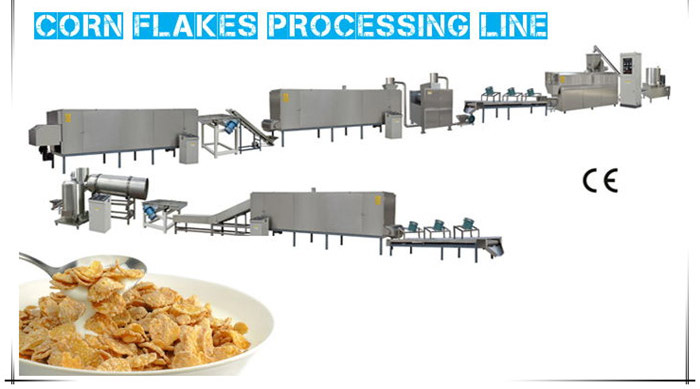

The Manufacturing Process

The manufacturing process of corn flakes using an extrusion line can be summarized as follows:

Mixing: The raw materials, including cornmeal, sugar, and salt, are blended in the mixer.

Extrusion: The mixture is fed into the extruder, where it is cooked and shaped into the desired form. The extrusion process involves the use of heat and pressure to cook the mixture and force it through the die, shaping it into the desired form.

Flaking: The extruded mixture is fed into the flaking machine, where it is flattened into thin flakes.

Drying: The flakes are then fed into the drying oven, where moisture is removed, making them crispy.

Sugar Coating: The sugar coating machine adds a layer of sugar to the corn flakes, giving them a sweet taste.

Packaging: The finished product is then packed into bags, boxes, or other containers using the packaging machine.

Advantages of a Corn Flakes Extrusion Line

Efficiency: The corn flakes extrusion line is highly efficient, producing large quantities of corn flakes in a short amount of time. This efficiency reduces production costs and increases productivity.

Consistency: The extrusion process ensures that each corn flake is uniform in size and shape, providing consistency in the final product.

Quality: The extrusion process ensures that the corn flakes are fully cooked, making them easy to digest and highly nutritious.A

Shelf Life: The corn flakes produced using the extrusion line have a long shelf life, making them ideal for mass production and distribution.

Conclusion

The corn flakes extrusion line is a highly efficient and versatile machine used in the production of corn flakes. The extrusion process ensures that each corn flake is uniform in size and shape, providing consistency in the final product. The extrusion line's efficiency, consistency, customization, quality, and long shelf life make it an essential tool in the food manufacturing industry. As technology continues to evolve, the corn flakes extrusion line's performance will continue to improve, further enhancing its value in the years to come.

Are you interested in learning more about steel coils for sale and how they can benefit you? Contact us today to secure an expert consultation!