Understanding Ingredients and Nutrition in Granola Bars

Granola bars serve as a compact and portable nutritional source, typically composed of oats, nuts, honey, dried fruit, and occasionally chocolate. The key ingredient, oats, is abundant in dietary fiber, contributing to heart health. Nuts offer a valuable plant-based protein and monounsaturated fats, promoting overall well-being. Honey serves as a natural sweetener and binder, while dried fruits provide a concentrated source of vitamins and fiber. Some granola bars incorporate chocolate or other sweet additions, enhancing taste and consumer appeal but also increasing sugar content. It is crucial to read the packaging to grasp the nutritional content of each bar, as it can vary significantly based on the specific mix of ingredients employed.

The Evolution of Granola Bar Production

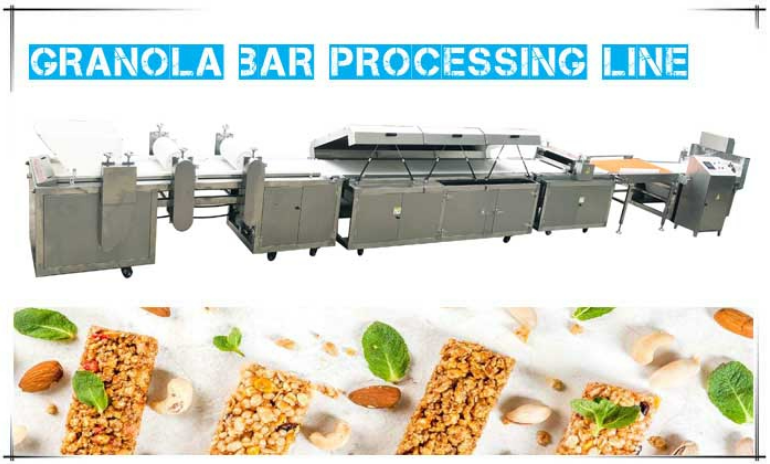

The production of granola bars has undergone significant evolution, propelled by technological advancements and changing consumer preferences. In its early stages, granola bars were manually mixed and shaped before baking, constituting a labor-intensive and inconsistent process. The introduction of automation revolutionized the production process, improving efficiency, consistency, and scalability.

Modern granola bar production lines now integrate precision measuring and mixing equipment, ensuring each bar maintains the exact proportion of ingredients. Automated shaping and baking machines guarantee uniform bar size and quality, while advanced packaging solutions play a vital role in preserving freshness and extending shelf life.

Furthermore, the industry's response to the growing demand for healthier, organic, and allergen-free options has led to the adoption of new production processes and stringent quality controls. These advancements enable manufacturers to keep pace with the increasing global demand for this nutritious and convenient snack.

Production Line Basics

Critical Machines in Granola Bar Manufacturing

The granola bar production process involves several pivotal machines meticulously designed to establish a streamlined, efficient, and high-quality production line.

1. Ingredient Batching Systems:

- Precision machines that accurately measure ingredients for each granola bar batch, ensuring consistent taste and nutrition.

2. Mixing Machines:

- Following ingredient batching, these devices blend the ingredients thoroughly, ensuring a uniform distribution of components.

3. Forming Machines:

- These machines press the mixed ingredients into the desired bar shape and size.

4. Baking Ovens:

- Formed bars are conveyed into baking ovens, where they achieve the ideal texture and consistency through the baking process.

5. Cooling Conveyors:

- After baking, bars are gradually cooled on conveyors to lower their temperature before the packaging stage.

6. Packaging Machines:

- Cooled bars are finally wrapped and sealed in their packaging. Some machines also print expiration dates or batch numbers on the packaging.

7. Quality Control Systems:

- Throughout the entire process, advanced quality control systems monitor the product, ensuring each bar meets standards for size, weight, and overall quality.

By integrating these machines into a cohesive production line, manufacturers can mass-produce granola bars while maintaining consistent quality and efficiency.

Automation and Efficiency in the Production Line

Automation plays a pivotal role in enhancing the efficiency and productivity of the granola bar production line. Advanced automated systems are seamlessly integrated into every stage of the manufacturing process, eliminating manual intervention and reducing the risk of human error. These systems expedite the production process, enabling the achievement of high-volume production targets within a shorter timeframe.

Furthermore, automation ensures a consistent standard of quality throughout the production run by providing precise control over process parameters. The precision and repeatability in operations achieved through automation offer a distinct advantage over manual processes. Additionally, automation allows for continuous, 24/7 production without the need for shift changes, significantly enhancing manufacturing efficiency.

Through the integration of automation, the granola bar sheeting cutting machine can deliver high-quality products consistently, at scale, and realize substantial cost efficiencies.

FAQ

Q: What Is The Production Process Of Granola Bars?

A: The production process of granola bars involves blending ingredients such as oats, nuts, honey, and occasionally chocolate or dried fruit, followed by pressing the mixture into a bar shape and baking it.

Q: What Machinery Is Required For Granola Bar Production?

A: Machinery required for granola bar production includes bar making machines, extruders, forming machines, and cutting equipment for shaping and cutting the bars.

Q: What Are The Key Ingredients Used In Granola Bar Manufacturing?

A: Key ingredients used in granola bar manufacturing are oats, nuts, honey, puffed rice, chocolate, and protein to create a nutritious and delightful snack.

Q: How Are Cereal Bars Different From Granola Bars?

A: Cereal bars typically contain grains and are often considered a breakfast option, while granola bars specifically contain oats and are known for their chewy and crunchy texture.

Q: What Are The Main Considerations For A Successful Granola Bar Production Line?

A: A successful granola bar production line should prioritize efficient machinery, consistent quality control, and proper packaging for the finished bars.

Q: What Is The Role Of An Automatic Bar Making Machine In Granola Bar Production?

A: An automatic bar making machine streamlines the production process by shaping and forming the granola bar mixture into consistent bars without the need for manual intervention.

Q: How Can One Get Involved In The Granola Bar Industry As A Manufacturer?

A: Getting involved in the granola bar industry as a manufacturer requires an investment in the necessary machinery, understanding of food production regulations, and the development of unique recipes for granola bars.

Q: What Are The Packaging Options For Finished Granola Bars?

A: Packaging options for finished granola bars may include individual wrapping for single bars, as well as multipack options for selling multiple bars together.

Q: What Are Some Popular Variations Of Granola Bars In The Snack Food Industry?

A: Some popular variations of granola bars in the snack food industry include protein bars, energy bars, and chocolate-covered granola bars to cater to different consumer preferences.

Q: How Does The Use Of An Extruder Benefit The Production Of Granola Bars?

A: The use of an extruder helps efficiently mix and form the granola bar mixture, allowing for consistent production and shaping of the bars with minimal manual effort.